Solution n°1

Transportable Cleanrooms

Our Clean Cube Modules solve multiple problems common in the high tech industry. Place them on a parking lot, flat roof, field and you can grow and expand quickly. This concept allows for a flexible planning and expansion of your clean room capacity. The modules can also be attached to existing buildings that are not suitable to accommodate a state of the art clean room. This was already done on several occasions, thus allowing the company to continue at the existing site. If your business plan limits investments, SIT offers you to lease your clean room. This is especially interesting for startups or a product launch where the risk needs to be tightly managed. This will also bind less capital in facilities which in turn is available for the increase in cash-flow during such a period.

Solution n°1

Transportable Cleanrooms

Our Clean Cube Modules solve multiple problems common in the high tech industry. Place them on a parking lot, flat roof, field and you can grow and expand quickly. This concept allows for a flexible planning and expansion of your clean room capacity.

Solution n°2

Cleanroom Air Conditioning

To keep environmental parameters within specification is a critical element for multiple processes and indeed a key factor in any clean room installation. With our extensive range of Air Handlers SIT can achieve the stability and control you need. Besides keeping Temperature, Humidity and Pressure stable, our units are also able to run the complete clean room installations. This includes sluice control, monitoring and alarm handling as well as measuring and regulating air flows. In order to minimize down-time our Air Handlers can be equipped with a VPN-Modem to allow remote support access (IOT-capability). Data exchange with Lab Management Systems (LMS) is also possible through various protocols. Part of this product range are also our smart FFUs which can be equipped modularly with the functions you need: extra silent, cooling capacity, heating capacity, communication and control protocols.

Solution n°2

Cleanroom Air Conditioning

To keep environmental parameters within specification is a critical element for multiple processes and indeed a key factor in any clean room installation. With our extensive range of Air Handlers SIT can achieve the stability and control you need.

Solution n°3

Laminar Flow Units

Quality control is partially a risk-management process. A couple of integral steps usually define the quality of a product/process disproportionately. Those key aspects deserve and indeed are worth special attention. With SIT Laminar Flow environments one can achieve the desired parameters exactly where they matter most. This allows our clients to implement a controlled zone without having to redesign the whole process chain. It is also easier to access such a zone with material-flow and media supplies, especially if the demands are changing. This is for instance often the case in research facilities or prototype development. We are proud to enable various research facilities with cutting edge environments to play an important part in their discoveries.

Solution n°3

Laminar Flow Units

Quality control is partially a risk-management process. A couple of integral steps usually define the quality of a product/process disproportionately. Those key aspects deserve and indeed are worth special attention. With SIT Laminar Flow environments one can achieve the desired parameters exactly where they matter most.

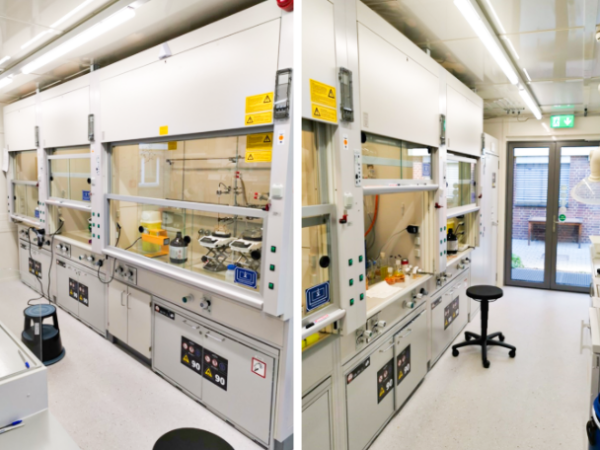

Solution n°4

Turn Key System

Building a clean room hull with walls, ceiling, lights and doors is only one part of an integrated system. An operational clean room as a productive environment has a lot more layers than what is visible at a first glance. SIT will integrate all the infrastructures necessary to ensure that the installation complies with all specs and has all the services ready for production.

- The air treatment and ventilation system

- Sensors and Actuators for measuring and regulating temperature, humidity, air pressure etc.

- Infrastructure and distributions for process gasses, vacuum, DI-Water, CDA etc.

- Electrical cabinets with plc with the software to regulate the clean room parameters

- HMI touch screens to visualize all parameters and adjust all setpoints.

- Monitoring and Alarmhandling of all critical parameters

Solution n°4

Turn Key System

Building a clean room hull with walls, ceiling, lights and doors is only one part of an integrated system. An operational clean room as a productive environment has a lot more layers than what is visible at a first glance. SIT will integrate all the infrastructures necessary to ensure that the installation complies with all specs and has all the services ready for production.

Download our resources!

Our project reports and product data sheets will give you an overview of our wide range of know-how and the versatility of our solutions. Browse through them and do not hesitate to contact us. We are always looking for new challenges!

Download our resources!

Our project reports and product data sheets will give you an overview of our wide range of know-how and the versatility of our solutions. Browse through them and do not hesitate to contact us. We are always looking for new challenges!